What is Alloy Steel Casting?

Alloy steel casting is a steel casting process that is one kind of alloy castings. It is alloyed with numerous elements in total amounts between 1.0% and 50% by weight. The alloy casting can improve its mechanical properties.Alloy steel castings are divided into cast alloy structural steel and special purpose alloy cast steel according to their applications. The former is low to medium alloy cast steel, mainly used to make general mechanical structural components. The latter is mostly high alloy cast steel, such as wear-resistant cast steel, stainless acid resistant cast steel, heat-resistant cast steel, casting alloy tool steel, etc.

Alloy steel is divided into two categories: low alloy steel and high alloy steel. Low alloy steel is the most common alloy steel in investment casting.

Compared with carbon steel, alloy steel has many good properties such as strength, hardness, toughness, wear resistance, corrosion resistance and hardenability. If your castings cannot meet these properties, our heat treatment workshop will help you improve some of these improved properties.

Besides the Alloy Steel Castings Products, there are

chrome alloy castings,

copper-nickel alloy casting,

copper-zinc alloy castings,

gold alloy castings,

nickel alloy castings,

high alloy castings,

high nickel alloy castings.

Their difference is from the content of each alloy element. please check the Alloys Cast and Chemical Composition document.

| Grade | C | Si | Mn | S P | Cr | Ni | Mo | Cu |

| ZG40Mn | 0.35-0.45 | 0.30-0.45 | 1.20-1.50 | ≤0.030 | ||||

| ZG40Mn2 | 0.35-0.45 | 0.20-0.40 | 1.60-1.80 | ≤0.030 | ||||

| ZG50Mn2 | 0.45-0.55 | 0.20-0.40 | 1.50-1.80 | ≤0.030 | ||||

| ZG20SiMn | ≤0.023 | ≤0.60 | 1.00-1.50 | ≤0.025 | ≤0.30 | ≤0.40 | ≤0.15 | |

| ZG35SiMn | 0.30-0.40 | 0.60-0.80 | 1.10-1.40 | ≤0.030 | ||||

| ZG35SiMnMo | 0.32-0.40 | 1.10-1.40 | 1.10-1.40 | ≤0.030 | ≤0.30 | ≤0.30 | 0.20-0.30 | ≤0.30 |

| ZG35CrMnSi | 0.30-0.40 | 0.50-0.75 | 0.90-1.20 | ≤0.030 | 0.50-0.80 | |||

| ZG20MnMo | 0.17-0.23 | 0.20-0.40 | 1.10-1.40 | ≤0.030 | ≤0.30 | ≤0.30 | 0.20-0.35 | ≤0.30 |

| ZG55CrMnMo | 0.50-0.60 | 0.25-0.60 | 1.20-1.60 | ≤0.030 | 0.60-0.90 | ≤0.30 | 0.20-0.30 | ≤0.30 |

| ZG40Cr | 0.35-0.45 | 0.20-0.40 | 0.50-0.80 | ≤0.030 | 0.80-1.10 | |||

| ZG34CrNiMo | 0.30-0.37 | 0.30-0.60 | 0.60-1.00 | ≤0.025 | 1.40-1.70 | 1.40-1.70 | 0.15-0.35 | |

| ZG20CrMo | 0.17-0.25 | 0.20-0.45 | 0.50-0.80 | ≤0.030 | 0.50-0.80 | 0.40-0.60 | ||

| ZG35CrMo | 0.30-0.37 | 0.30-0.50 | 0.50-0.80 | ≤0.030 | 0.80-1.20 | 0.20-0.30 | ||

| ZG42CrMo | 0.38-0.45 | 0.30-0.60 | 0.60-1.00 | ≤0.025 | 0.80-1.20 | 0.20-0.30 | ||

| ZG50CrMo | 0.46-0.54 | 0.25-0.50 | 0.50-0.80 | ≤0.030 | 0.90-1.20 | 0.15-0.25 | ||

| ZG65Mn | 0.62-0.70 | 0.17-0.37 | 0.90-1.20 | ≤0.030 | ≤0.25 | ≤0.25 |

As mentioned above, there are several types of alloy castings. Each type has its own advantages and disadvantages. Therefore, there are many factors to consider when choosing a casting alloy. Strength, durability, yield, corrosion resistance, cost, stability, etc.

If your project requires components with high strength and corrosion resistance, aluminum or copper-based alloys can be effective choices. The alloy you use for casting depends on what your project requires.

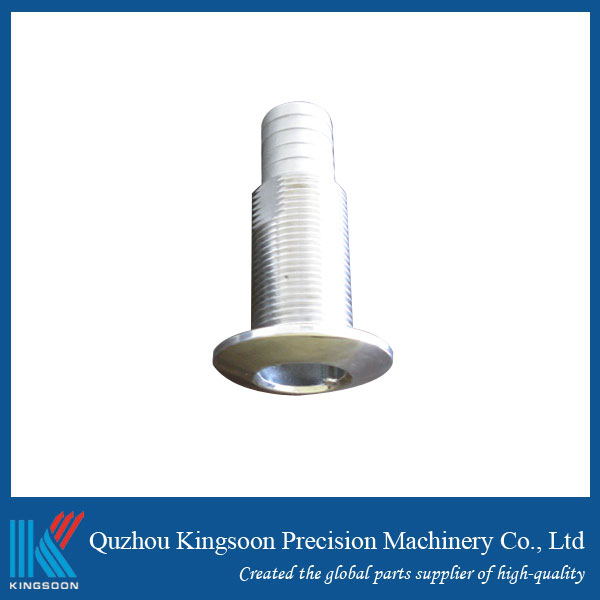

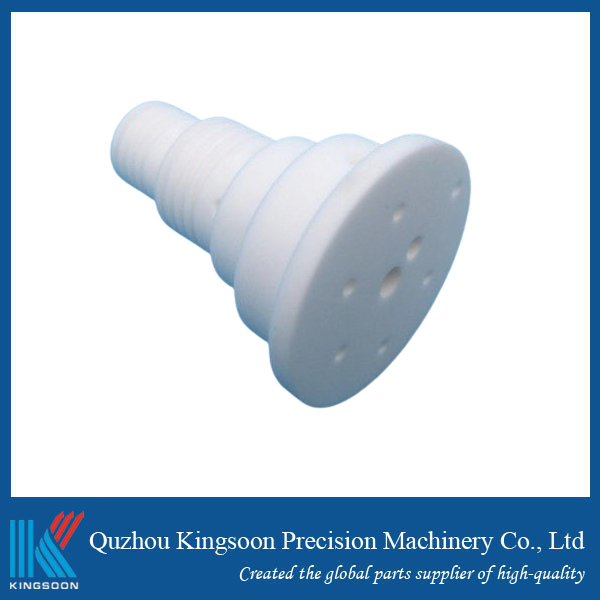

Traditionally, alloy steel castings have better properties than carbon steel castings. In comparison, alloy steel castings are more expensive due to their higher material costs. Alloy steel castings are widely used in industrial applications such as bucket teeth, agricultural wear parts, and many other industrial components that use cast alloy steel parts for their work.

Kingsoon is a precision alloy steel casting manufacturer and exporter from China. We have our own foundry and machining plant. At present, we export alloy steel castings to Japan, Germany, the UK and other countries. The quality of our products has been recognized by customers and we have established long-term cooperative relationships. If you have any questions about alloy steel casting projects, please feel free to contact us. We will get back to you as soon as we receive your message.